Falls from Height continue to be a major problem and potential killer across all industry. Health and Safety Executive (HSE) figures point to Falls from Height as being the number one killer within the Construction sector. However, it need not be so as with correct training and supervision there is no reason why deaths cannot be avoided.

Unfortunately, the current accident statistics may only be the tip of the iceberg, as the

workforce in some industries such as Construction and Entertainment can be casual, freelance or sub-contractors which can result in many accidents not being reported (HSE 21.09.00).

It is important to recognise that a duty of care is placed on both managers and workers alike to ensure legal compliance is met. This involves a high degree of commitment to safety from everyone to ensure appropriate systems are in place that allow for personnel to be suitably trained.

Principles of Working at Height

In addressing the issues surrounding Working at Height, it is important to gain an understanding of the main principles involved.

Protection from falling is needed where there is any unprotected side or edge with a risk of falling over 2m. There are a variety of ways of applying the fall protection needed, but the first consideration must always be that of safety and the risks involved to workers. As such, in all cases where Working at Height is involved a Risk Assessment should be carried out to establish what Health and Safety measures need to be adopted to avoid or reduce risk. Consideration should be given to:-

In addition to the above process, a manager will establish what is the best method to adopt in order to carry out the work. The individual must weigh up the practicalities involved and balance this against the risk presented to the worker by the chosen means of access. There exists what is termed as a "hierarchy of risk" based upon risk and practicality. The higher up the hierarchy a method of access is considered to be, the lesser the risk associated with it.

Permanently Installed Access is at the top of the hierarchy as it has the least amount of risk associated with it. This involves the installation of walkways and gantries, and is appropriate where a site must be accessed regularly for routine maintenance.

Next in the hierarchy is Temporary Working Platforms such as scaffolding, cradles and mobile platforms. This method requires the staff using them to be trained in their use.

Bottom of the hierarchy and therefore most risky is the use of Personal Protective Equipment (PPE) and Fall Arrest Techniques. This involves the use of PPE to catch a falling worker and prevent serious injury. In addition, PPE is also used in Work Positioning and Work Restraint techniques. As the majority of accidents occur during the application of these methods, these areas will be examined in detail.

1) Work Restraint

Work Restraint is a technique that involves the use of PPE to prevent a worker entering an area where there is a risk of a fall from height. This means that a worker is effectively restrained to an anchor point and is a technique often used when working on flat roofs or open decks. Careful placement of the anchor point can mean that a single point can cover a large safe working area.

2) Work Positioning

Work Positioning is a technique for supporting a person whilst working using a PPE in tension, to prevent a fall. This is opposed to Fall Arrest where the PPE is used to catch the worker in the event of a fall.

Where the workers weight is supported primarily by the structure e.g. Climbing scaffolding or a ladder, then a single line system will provide backup should the worker fall from the structure. Where the worker's weight is being totally supported by the PPE, then a separate backup system is necessary to prevent a fall, should the primary system fail.

Apart from preventing falls a work positioning system can be used by a worker to help maintain balance and can be seen as a "third arm", leaving the worker's hands free to carry on with the work.

3) Fall Arrest

Fall Arrest is a technique that makes use of items of PPE to stop a falling person under safe conditions.

As a worker falls and is caught by the Fall Arrest equipment, it is important that any force applied to the worker must not be in excess of 6kN (600kg). This can be achieved through the use of a shock absorber, such as tear-out lanyards, and ensuring that lanyards are always anchored above head height to reduce the impact forces of a fall.

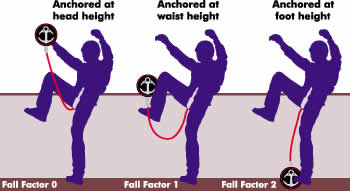

The Fall Factor is a figure used to express the seriousness of a fall. It is the relationship between the length of the fall and the length of rope available and can be calculated like this:

Fall Factor = Length of Fall Rope in System

The Fall Factor is influenced by the relative position of the anchor and the worker. The maximum possible Fall Factor in normal conditions is two - where the climber falls twice the length of his attachment. See illustration:

The Fall Factor is influenced by the relative position of the anchor and the worker. The maximum possible Fall Factor in normal conditions is two - where the climber falls twice the length of his attachment. See illustration:

Personal Protective Equipment

It is important to recognise that the incorrect application of Personal Protective Equipment is just as bad as not using anything at all. PPE used in the wrong application can prove fatal. As such, managers and workers must both gain an insight into the various types of equipment and for which applications they are most suitable.

Harnesses:

One of the most important and critical pieces of PPE is the full body harness. In particular, the choice of connection points is an important consideration when using harnesses. For example, the rear or chest connection points can only be used in a Fall Arrest application, and if a harness has an integral waist belt with side connection points they must only be used for Work Positioning or Work Restraint.

Lanyards:

Lanyards are another key part of the PPE used in Fall Arrest. The length of a lanyard should not exceed 2 meters, and when used for Fall Arrest in conjunction with a full body harness, the lanyard should incorporate an Energy Absorber.

NB: Consideration must always be given to the height at which you are working, plus your own height and the length of the fully extended lanyard should a fall occur. The system needs to operate and be functional to prevent anyone hitting the ground before preventing the fall.

Fall Arrestors:

Arrestors come in a variety of forms including self retracting. They are designed to work in vertical or near vertical applications only. They should not be used in horizontal applications, as in the event of a fall the user would swing back to a vertical position exposing themselves to an unacceptable length of fall and the risk of striking something on the way.

Inspection & Care of PPE:

For PPE to work effectively, it needs to be in good condition and operating as the manufacturer intended. Careful use and storage, in addition to regular inspection of the equipment will help ensure its safe use. Before use, each piece of equipment should be checked for any signs of damage or excessive wear. Check the correct functioning of locking mechanisms on connectors and inspect all webbing for cuts, burns, frays and chemical attack. If any defects, excessive wear or corrosion is found, the item must be rejected and not used. Ideally, harnesses and lanyards should be dealt with in a similar way to slings - they should be tracked and records kept of inspections.

Quality of Equipment:

The need to avoid cutting corners when buying PPE cannot be stressed enough.

Paul Fulcher, LGH Group Operations Director and Chairman of the Lifting Equipment Engineers Association (LEEA), comments, "We refuse to compromise safety by using a cheap, poor quality product, for the sake of saving a few pounds on the hire price. We believe that customers should question whether they are actually paying enough for their lifting equipment, as we believe that some other hirers are putting price ahead of safety."

Lifting Gear Hire, part of LGH Group, put their trust in the Sala and Protecta ranges of Harnesses and Fall Arrest equipment. Used daily by Lifting Gear Hire customers all over the UK, Sala and Protecta Harnesses, Inertia-Reel Fall Arestors and Lanyards are available both for hire or sale from any one of Lifting Gear Hire's 34 branches. Servicing of customers' own Sala or Protecta equipment is also available at a number of locations.

All of Lifting Gear Hire's stock of Fall Arrest equipment is serviced and inspected at regular intervals, with every piece of hire equipment inspected every time it goes out on hire.

Training:

Falls from height accounted for 50% of all fatal accidents on construction sites in 2000. That equates to 38 deaths and 1540 major injuries, which makes for sobering statistics. In fact the Health and Safety Executive (HSE) is so concerned with the situation that they are undertaking a ten-year initiative covering safe working at height across all industries.

Andrew East, a principal health and safety inspector with the HSE, outlined that a workforce needs training in how to use PPE as the correct use of the equipment is not always obvious. Mr. East explained that he has seen many instances of equipment being used incorrectly, including some sites where harnesses were being worn upside down.

Richard Foster, Head of The Lifting Equipment Training Initiative (LETI), suggests, "The first step towards ensuring safe working at height is through training. The responsibility lies with the employer to make sure that their staff are correctly trained for the job they are performing."

LETI offers a course entitled Height Awareness and Harness Inspection, which covers training in risk assessment, fall protection techniques, and the selection and inspection of equipment. The one-day course also offers a practical training and assessment element.

Learn the Lesson:

Unfortunately many companies gain their knowledge of safe Working at Height after an accident. In many instances, these accidents are perfectly avoidable, through the use of the correct techniques and equipment.

The ideal is to reduce the need to work at height at all. If a safer alternative means of working can be found then this is always the best case. However, in the real world it must be accepted that there are instances where working at height is inevitable and unavoidable. In these cases, a thorough assessment of risk should be undertaken, with competent, trained personnel, using the right equipment to perform the work. Under these conditions, work at height can be undertaken in complete safety, as long as the right procedures are implemented and an appropriate degree of care is taken.

A Longmire

Technical Director

LGH Group plc